Messrobotic

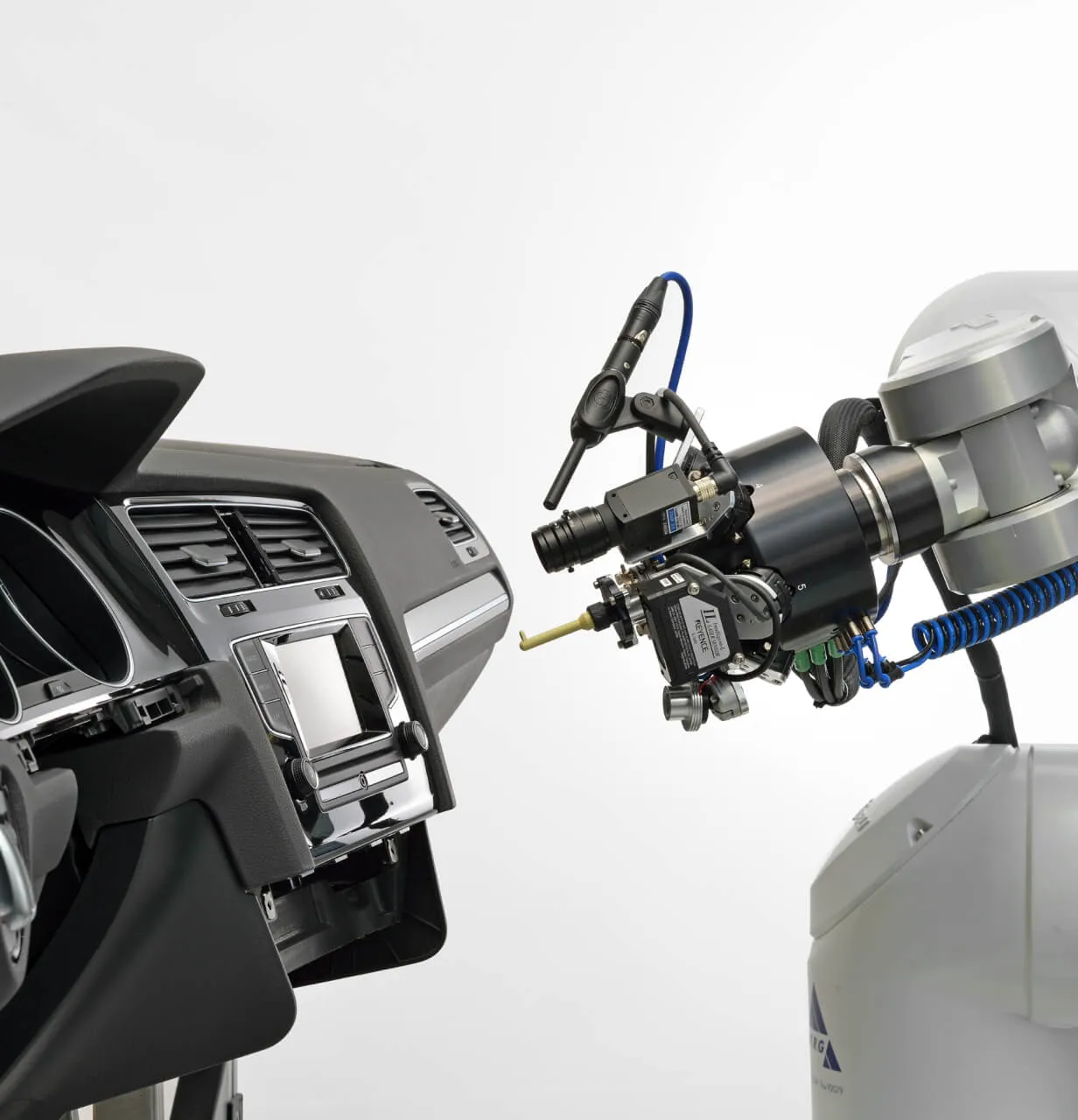

Messrobotic ist die Kombination aus Roboter, Mess- und Prüfsensorik, externer Messtechnik, Schnittstellen und der Standard Messsoftware RobFlow©, um Prüfabläufe im Drag & Drop Verfahren programmieren

zu können.

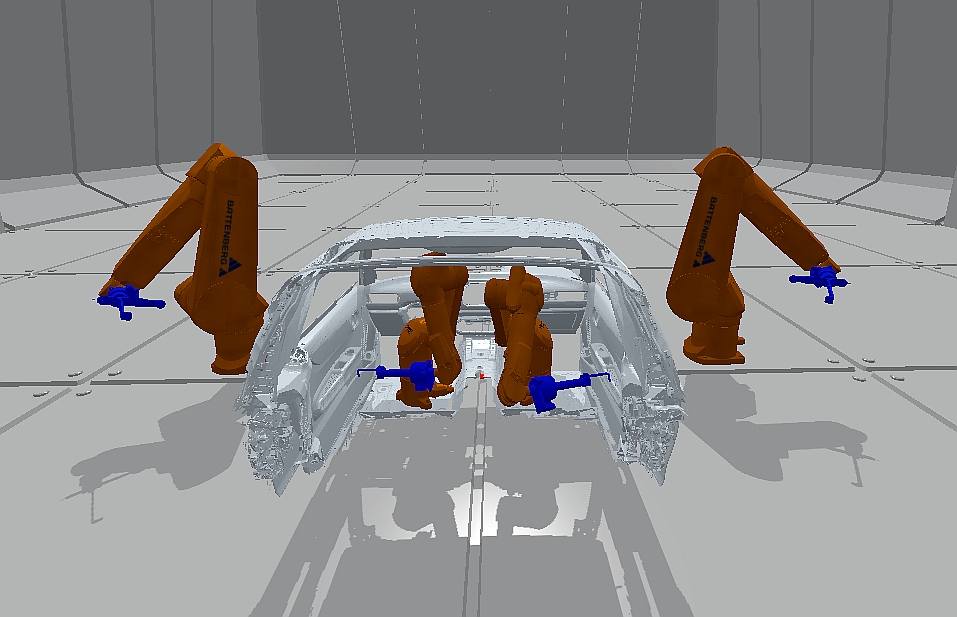

RobSimulation

RobSimulation simuliert und optimiert virtuelle Prüfabläufe für Messroboter, minimiert manuelle Prüfaufgaben vor Ort und schafft hochflexible Prüfzellen mit kurzen Anlaufzeiten.

robmobil

RobMobil ist ein autonomer mobiler Roboter (AMR) mit 7-achsigem Cobot und Messsensorik, der eigenständig Qualitätsprüfungen an frei wählbaren Prüfpositionen durchführt, insbesondere für funktionale Fahrzeugabsicherungen im Innen- und Außenbereich.

RobFlow©

Die Messsoftware RobFlow© bildet die Kernkompetenz der Battenberg Messrobotic für das Messen, Analysieren und Bewerten von objektiven Qualitätsmerkmalen.

Mehrwert Battenberg.

In enger Zusammenarbeit mit unseren Kunden hat sich die Messrobotic zum Standard für funktionelle

Komponentenprüfungen, sowie Referenz und Benchmark für die vertrauensvollen Qualitätsbeurteilungen im Audit zwischen OEMs, Lieferanten und Dienstleistern entwickelt.

Dies bestätigt unseren Export in weltweite Produktionsanlagen unserer Kunden, die wir ebenso mit Training, Service und Wartungen unterstützen.

Abdeckung der gesamten Produktwertschöpfungskette

Heute umfasst unser Portfolio Messrobotic Lösungen für die gesamte Produktwertschöpfungskette von Forschung und Entwicklung, über Klimaroboter in der Klimakammer bis zu End-of-Line-Prüfungen in der Produktion.

Funktionelle Absicherung der Interieur und Exterieur Komponenten von Fahrzeugen

Besondere Schwerpunkte bilden die funktionellen Absicherungen von Interieur und Exterieur Komponenten von Fahrzeugen, mit stationären und mobilen Messrobotern oder Cobots, sowie wählbaren Traglasten und Reichweiten.

Hohe Wettbewerbsvorteile und Kosteneinsparungen

Mit der Konvergenz von virtueller und realer Roboterwelt eröffnen wir unseren Kunden hohe effektive Wettbewerbsvorteile, die im Rahmen eines Ökosystems auch zu erheblichen Kostenvorteilen führen.

Enge Zusammenarbeit mit unseren Kunden

Wir arbeiten sehr eng mit unseren weltweiten Kunden zusammen, um sicherzustellen, dass unsere Produkte und Lösungen ihren spezifischen Anforderungen und Erwartungen entsprechen. Dabei zeichnen sich unsere Roboterapplikationen durch Effektivität, Nachhaltigkeit und Effizienz, innerhalb eines umfassenden Ökosystems aus.

Referenzkunden

Serviceangebot

Neben unserem After-Sales-Service in der Messtechnik, der die Sensorkalibrierung und Roboterwartung umfasst, bieten wir auch Mietsysteme für die Messrobotic an. Workshops, Schulungen, Machbarkeitsstudien und Auftragsmessungen sind ebenfalls Teil unseres umfassenden Dienstleistungsangebots.

Mehr dazu

Auftragsmessungen

Sensorkalibrierung

Roboterwartungen

Machbarkeitsstudien

Battenberg Robotic Mietsysteme

Battenberg Robotic Workshops

Messrobotic Schulungen

Mehr über die Firma Battenberg

Seit 1982 arbeiten wir sehr erfolgreich in der Messrobotic und erfüllen mit unserer hochpräzisen Battenberg Robotic die Forderungen und Erwartungen nach flexiblen, reproduzierbaren und transparenten Qualitätsprüfungssystemen in der Messrobotic.

- Hochpräzise, komplexe und reproduzierbare Qualitätsprüfungen

- Wirtschaftliche Lösungen, flexibel und mehrfach anwendbar

- Bedienerfreundliche Messsoftware, schnell erlernbar und einfache Handhabung

Neuigkeiten

Simulation Türprüfung

Simulation der Tür- und Heckklappen- Prüfabläufe am virtuellen Fahrzeug

RobSimulation & Multiroboter

BMW entscheidet sich für die Software RobSimulation

Roboterforum 2024

Battenberg ROBOTIC präsentiert am 21. März 2024 im VILA VITA Rosenpark Hotel in Marburg zwei innovative Meilensteine der Messrobotic. Interessante Vorträge und praktische Anwendungen geben Raum für den Austausch und anregende Gespräche.

Leuchtdichtenmessung bei Volkswagen

Simulation und reale Messung der Leuchtdichte im Hause Volkswagen

Aviation Forum 2023

Battenberg ROBOTIC präsentierte mit der Software RobSimulation und der mobilen Messrobotic RobMobil (AMR) zwei Meilensteine auf dem Aviation Forum 2023.

.jpg)

.bmp)

.jpg)